In the thermal power plant, the high temperature and high pressure steam produced by the boiler enters the steam turbine to do work to drive the generator to generate electricity, and the exhaust steam is discharged from the tail of the steam turbine into the condenser for the first heat transfer. The heat is transferred to cooling water and steam is condensed into condensate water which is sent back to boiler by feed pump into next cycle.

In the thermal power plant, the high temperature and high pressure steam produced by the boiler enters the steam turbine to do work to drive the generator to generate electricity, and the exhaust steam is discharged from the tail of the steam turbine into the condenser for the first heat transfer. The heat is transferred to cooling water and steam is condensed into condensate water which is sent back to boiler by feed pump into next cycle.

The cooling water heated in the condenser enters the indirect air cooling radiator through the circulating water pump. Under the natural drought force of the cooling tower, the cooling water transfers the heat to the air and then cool down and then return to the condenser for the next heat exchange cycle.

The condenser of indirect air cooling system can be mixed or surface condenser. Most indirect air cooling towers use natural ventilation cooling towers, concrete towers or steel towers can be selected.

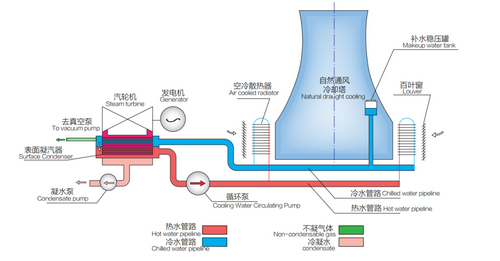

1.Indirect dry cooling system with surface condenser

The exhaust steam enters into the surface condenser to transfer heat to cooling water and condenses into condensate water to return to the thermal system. The cooling water heated up is pumped into the aluminum tube fin radiator around the indirect air cooling tower and get temperature lowered down by ventilation air. the low temperature cooling water will then go back to condenser for next cycle.

Features:

1、The radiator adopts the aluminum tube aluminum fin, vertical arrangement in the outside of the air cooling tower ;

2、The cooling water system and the condensate water system are separated, and the water quality of the two systems can be controlled according to their respective requirements;

3、The circulating water system is a closed system with low lift and low power of the pump.

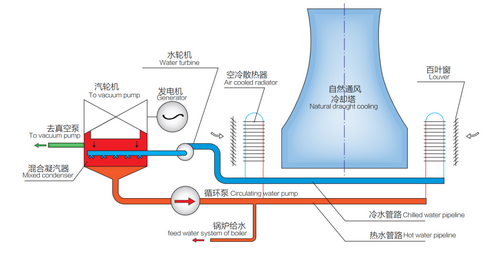

2.Indirect dry cooling system with mix condenser

The steam turbine exhaust steam enters the mixed condenser, directly contacts the circulating cooling water from the indirect air cooling tower to heat transfer, and get condensed. Steam condensate is mixed with cooling water, about 2% of the mixed water is sent back to the regenerative system by condensate pump, and the remaining 98% of the mixed water is fed into the air cooling tower radiator by circulating water pump. After cooling, the circulating water is returned to the mixed condenser for the next cycle.

Feature:

1、The radiator adopts aluminum tube aluminum fin and is arranged vertically outside the indirect air cooling tower;

2、Small footprint, less capital investment;

3、The hybrid condenser has small volume and can be arranged in the lower part of the turbine;

4、Short steam turbine exhaust pipe, small vacuum system.

3.Tube bundle introduction

Aluminum tube aluminum fin are adopted for tube bundles for indirect dry cooling systems with the following characteristics:

01/ High heat transfer efficiency

The base tube and fin of the heat transfer element are made of pure aluminum. The thermal conductivity of aluminum is 4 times that of steel, and the heat transfer efficiency is higher than that of steel heat exchanger.

02/ Low air side resistance

Through optimization, the open seam spoiler structure is used to enhance the heat transfer and reduce the resistance of the air side.

03/ Double passages &Reverse Counter- Flow Structure

The design makes the total heat transfer coefficient of air cooling radiator higher than that of single flow cross flow arrangement.

04/ Strong corrosion resistance

The surface forms a stable oxide layer with good corrosion resistance and avoids bimetallic corrosion. When the steel radiator stops, it needs nitrogen gas protection, the system is complex and the maintenance cost is high.

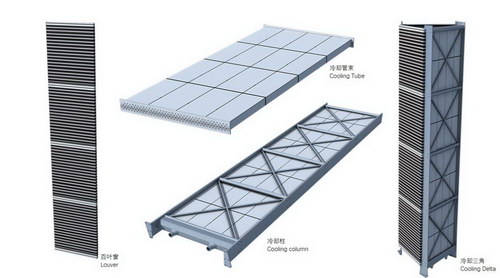

4.Cooling module introduction

Cooling tube bundle

A cooling tube bundle is generally composed of four finned tube modules and two ends of the tube plate expansion, is the basic unit of the indirect cooling radiator, every 2~4 cooling tube bundles can form a different height of cooling column.

Cooling column

The cooling column can be composed of several cooling tube bundles in series, and the two cooling tube bundles are fixed with bolts and connecting plates. Both ends of the cooling column are connected with the top water chamber and the bottom water chamber respectively, and the water chamber and the tube bundle plate are fixed with U bolts. Assemble cooling column, both ends of aluminum pipe joints are equipped with O rubber ring seal. The lower water chamber is provided with an inlet and outlet, and a partition is arranged in the middle to make the water flow into half (two rows) of pipes to the upper water chamber and then is folded back to the other two rows of pipes to form a double passages. The upper water chamber has an exhaust port to connect the riser exhaust air system. The material of water chamber is aluminum alloy.

Cooling delta

Two cooling columns are fixed on both sides of a triangular steel frame with an angle of about 50, and the third side is an air passage. A shutter is arranged on the air passage when the minimum ambient temperature is lower than 0℃, which is used to adjust the cooling performance and avoid the low cooling water temperature in winter. Triangular assembly is the basic installation unit, because it is triangular, so called cooling delta, cooling triangle also contains triangular cover plate, bottom plate and other components.

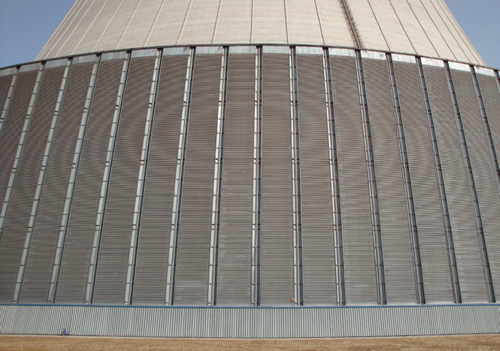

Cooling section

Multiple cooling triangles are arranged vertically along the periphery of the natural ventilation cooling tower. These cooling triangles are divided into several groups for easy operation and adjustment. Each group is equipped with an inlet and outlet manifold pipe which is equipped with an electric valve and a discharge valve. The water filling system, the water discharge system and the control system of each group conform one unit. Because each unit cooling triangle is fan-shaped around the tower, it is referred to as cooling fan section

Specify your requirements for tailored services (optional).